生產線及設備

陽極氧化處理綫

應用範圍及特點

- 手機零部件陽極氧化處理;

- 平板/電腦零部件陽極氧化處理;

- 可穿戴電子産品部件的陽極氧化處理。

- Mobile phone parts anodized;

- Tablet computer parts anodized;

- Wearable electronics components anodized.

電鍍鎳金綫

應用範圍及特點

- 配置高效的機械搖擺、震動與抖動系統;

- 鎳缸采用水浴加熱裝置、减少溫度波動;

- 采用多種方式防止鎳在缸體及管路上沉積,减少鎳缸藥水損耗。

- Configuration efficient mechanical swing, vibration and shake the system;

- Nickel tank use water bath heating device, reduce the temperature fluctuation;

- Using a variety of ways prevent nickel deposit in the tank and piping to reduce nickel cylinder syrup loss.

陶瓷電鍍綫

應用範圍及特點

- 陶瓷配件電鍍鎳金處理綫;

- 五金件鍍鎳金處理;

- 家電汽車零配件電鍍銅鎳鉻處理。

- Plating for ceramic fitting;

- Plating for hardwares;

- Household appliances and automatic parts copper & nickel & chrome plating.

全自動汽車塑膠電鍍綫

應用範圍及特點

- 汽車塑膠零件的電鍍銅、鎳、鉻等、化學沉銅、鎳的 自動生産綫;

- 配合智能程式可處理混鍍工藝。

- Plastic auto parts electroplating copper, nickel, chromium, etc., electroless copper, nickel, automatic production lines;

- With smart program can handle mixed plating process.

全自動PCB圖形電鍍設備

應用範圍及特點

- 采用藥水混流攪拌技術加獨立的藥水過濾系統;

- 配置高效的機械搖擺、振動與抖動系統;

- 采用半自動上下料機構减少勞動强度,提高生産效率;

- 采用可調陽極遮網及浮架設計,可獲得高均勻性的面 銅厚度。

- Using syrup mixed potion mixing technology plus aseparate filtration system;

- Configuration efficient mechanical swing, vibration and shake the system;

- Semi-automatic loading and unloading mechanism to reduce labor intensity and improve production efficiency;

- With adjustable anode cover nets and floating frame design, high availability of both surface copper thickness.

全自動磷化、鈍化、化成處理綫

應用範圍及特點

- 汽車零部件磷化皮膜處理;

- 各式五金配件磷化皮膜處理;

- 可穿戴電子産品部件的磷化皮膜處理;

- 可選配智能程式處理混鍍工藝。

- Auto spare parts phosphate coating;

- All kinds of metal parts phosphate coating;

- Wearable electronics components phosphate coating;

- Smart program system can handle mixed plating process is optional.

全自動板面鍍銅電鍍生産綫

應用範圍及特點

- 采用藥水混流攪拌技術加獨立的藥水過濾系統;

- 配置高效的機械搖擺、振動與抖動系統;

- 采用半自動上下料機構减少勞動强度,提高生産效率;

- 采用可調陽極遮蔽網及浮架設計,可獲得高度均勻性 的面銅厚度。

- Using syrup mixed potion mixing technology plus a separate filtration system;

- Configuration efficient mechanical swing, vibration and shake the system;

- Semi-automatic loading and unloading mechanism to reduce labor intensity and improve production efficiency;

- With adjustable anode cover nets and floating frame design, high availability of both surface copper thickness.

PTH處理綫

應用範圍及特點

- 配置高效的機械搖擺、震動與抖動系統;

- 鎳缸采用水浴加熱裝置,减少溫度波動;

- 采用多種方式防止鎳在缸體及管路上沉積,减少鎳缸藥水損耗。

- Configuration efficient mechanical swing, vibration and shake the system;

- Nickel tank use water bath heating device, reduce the temperature fluctuation;

- Using a variety of ways prevent nickel deposit in the tank and piping to reduce nickel cylinder syrup loss.

滾桶五金電鍍設備

應用範圍及特點

- 接插件的零件電鍍鎳金處理;

- 電子元器件零件電鍍鎳金處理;

- 滾桶細密高透水性的網孔設計;

- 配合智能程式可處理混鍍工藝。

- Connector parts nickel & gold plating;

- Electronic components parts nickel & gold plating;

- With smart program can handle mixed plating process.

- Barrel fine mesh high water permeability design;

機械手式電鍍設備

應用範圍及特點

- 緊固五金件電鍍鋅處理;

- 電聲五金零件電鍍鋅處理;

- 電子元器件五金零件電鍍鋅處理;

- 産量大操作成本低。

- Fastening matel parts zinc plating;

- Electroacoustic acoustic metal parts zinc plating;

- Electronic components metal parts zinc plating;

- Production of large and low cost operation.

全自動環形垂直升降電鍍生産綫(電鍍銅鎳鉻、化學沉銅沉鎳)

應用範圍及特點

- 衛浴五金件塑膠電鍍銅鎳鉻處理;

- 燈飾及家具五金塑膠件電鍍銅鎳鉻處理;

- 家電汽車五金塑膠件電鍍銅鎳鉻處理;

- 産量大操作成本低。

- Sanitation metal and plastic parts copper & nickel & chrome plating;

- Lighting & furniture metal and plastic parts copper & nickel & chrome plating;

- Appliances & auto metal and plastic parts copper & nickel & chrome Plating;

- Production of large and high effciency.

除膠渣及化學沉銅綫

應用範圍及特點

- 配置高效的機械搖擺、震動與抖動系統;

- 針對不同基板,除膠渣槽有多種不同設計;

- 化學銅槽攪拌均勻,過濾循環無死角設計。

- Configuration efficient mechanical swing, vibration and shake the system;

- According to the different substrate, desmear tank has a variety of different design;

- Chemical copper tank stirring uniform, filtration and circulation system without dead angle design.

快速冷凍綫

應用範圍及特點

- 肉類食品急速冷凍處理;

- 配合智能程式可同時冷凍不同産品;

- 多種冷凍液回收措施,减少冷凍液的消耗量;

- 配合機械手裝置,進行自動的上下料處理。

- Meat foods quick freezing treatment;

- The intelligent program can also frozen products;

- A variety of frozen liquid recovery measures reduce the consumption of frozen liquid;

- With the mechanical hand device, automatic loading and unloading process.

單臂+隧道式清洗機

應用範圍及特點

- 手機零部件超音波清洗處理;

- 精密衝壓件超音波清洗處理;

- 多種清洗方式保證産品潔淨度;

- 機械手分叠籃放置,效率高,産量大。

- Molbile phone parts ultrasonic cleaning process;

- Precision stamoings ultrasonic cleaning process;

- Various cleaning methods ensure the cleanliness of the product;

- Mechanical hand placed overlapping basket, high efficiency, large output.

玻璃、陶瓷清洗機

應用範圍及特點

- 手機、平板、可穿戴産品配件或視窗玻璃清洗;

- 晶元、太陽能産品清洗;

- 陶瓷配件清洗;

- 浸泡式清洗加超音波方式保證清洗潔淨度。

- Mobile phone & tablet & wearable electronics parts or displays cleaning;

- Wafer, solar energy products cleaning;

- Ceramic components cleaning.

- Using the immersion cleaning & ultrasonic cleaning methods ensure the cleanliness of the product.

壓鑄/CNC/衝壓後小鐵件五金件清洗機

應用範圍及特點

- 衝壓五金件除油清洗處理;

- CNC後五金加工件除油清洗 處理;

- 壓鑄件清洗 處理。

- Stamping parts degreasing cleaning processing;

- Mechanical parts degreasing cleaning processing;

- Die casting parts cleaning process.

卷對卷連續電鍍綫

應用範圍及特點

- 連接器料帶電鍍;

- 卷對卷自動收放料效率高。

- Continuous plating processes for electronic connector assemblies;

- With wheel structures on the loader & unloader, high efficiency, large output.

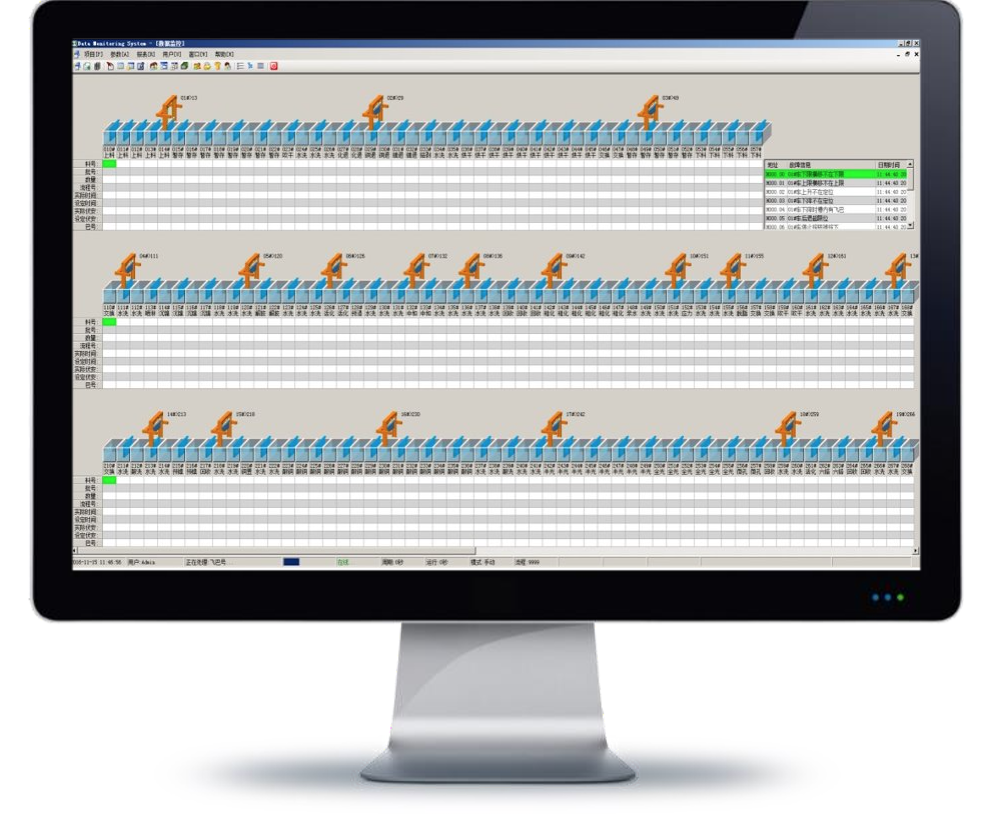

混鍍工藝控制及智能生産系統

應用範圍及特點

- 經常要修改處理時間、滴水時間;

- 天車行走工藝槽位需作變更;

- 希望幾種不同流程的産品同時混鍍;

- 新産品希望有對應的自動程序立即作測試的情况;

- 在測量鍍層不够的情况下自動返回補鍍;

- 經常有小批量、多品種工件生産;

- 可以查詢生産記錄,追溯工藝异常的原因。

- Modify the processing time, dripping water time frequently;

- Need change the processing path of crane;

- Hope several processes of product mix plating at the same time;

- New product need test the new auto programe immediately;

- If measuring coating is not enough thick, it will automatically return to the plating;

- There are often small amount and multiple product needs mix plating on the same line;

- You can query the production records, and traces the process of abnormal.

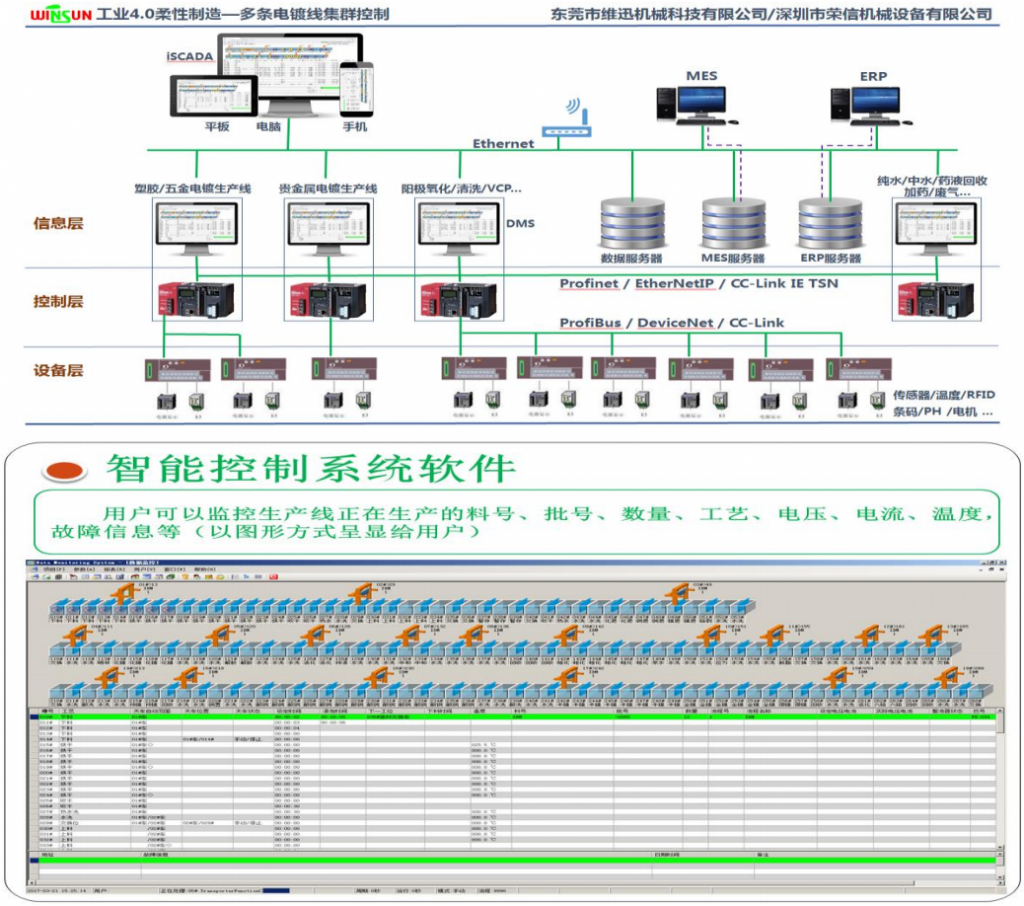

工业4.0柔性制造及控制软件

應用範圍及特點

- 經常要修改處理時間、滴水時間;

- 天車行走工藝槽位需作變更;

- 希望幾種不同流程的產品同時混鍍;

- 新產品希望有對應的自動程序立即作測試的情況;

- 在測量鍍層不夠的情況下自動返回補鍍;

- 經常有小批量、多品種工件生產;

- 可以查詢生產記錄,追溯工藝異常的原因;

- 多設備,多廠區工業4.0聯動生產及控製管理。

- Modify the processing time, dripping water time frequently;

- Need change the processing path of crane;

- Hope several processes of product mix plating at the same time;

- New product need test the new auto programe immediately;

- If measuring coating is not enough thick, it will automatically return to the plating;

- There are often small amount and multiple product needs mix plating on the same line;

- You can query the production records, and traces the process of abnormal.

廢氣處理及鮮風供給系統

應用範圍及特點

外部氣體進入塔體後,氣體進入填料層,填料層上有來自于 頂部的噴淋液體及前面的噴淋液體(二層噴淋),幷在填料 上形成一層液膜,氣體流經填料空隙時,與填料液膜接觸幷 進行吸收或中和反應,填料層的表面積依據廢氣處理量而設 定,對氣體流動又不致造成過大的阻力,經吸收或中和後的 氣體經除霧器收集後,經出風口排出塔外。

After the external air into the tower, the gas into the filler layer, with the spray liquid from the top and front of the spray liquid, and form a liquid film on the packing, the packing layer of gas through the packing voids, film in contact with the filler material and absorb or neutralize the reaction, the surface area of the filler layer is set based on the amount of the exhaust gas treatment of the gas flow and without causing too much resistance, and after the absorption of the gas or by the defogging after collected, the discharge outlet tower.